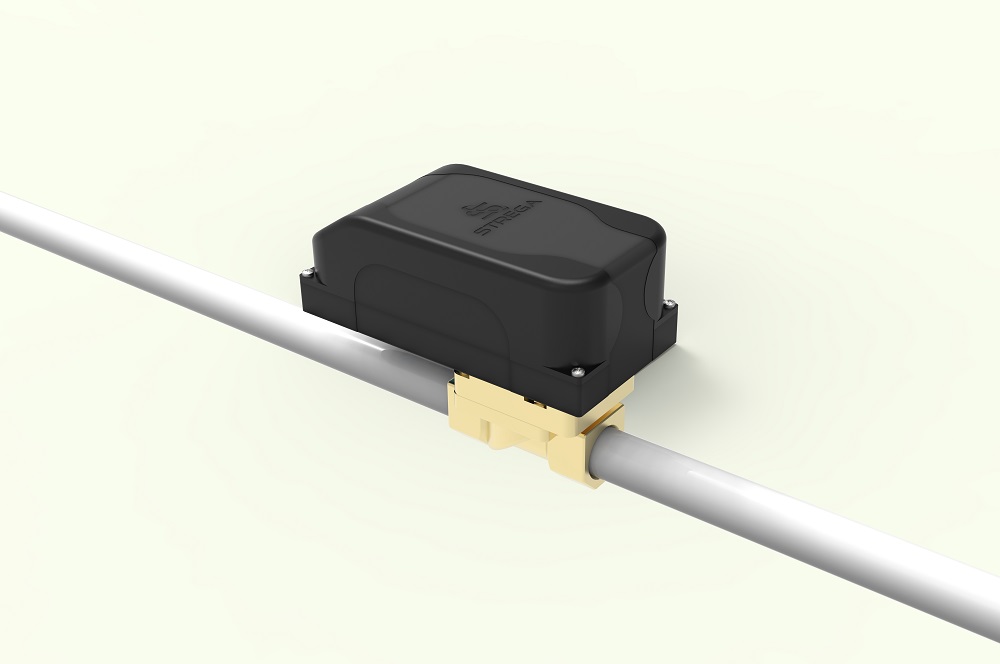

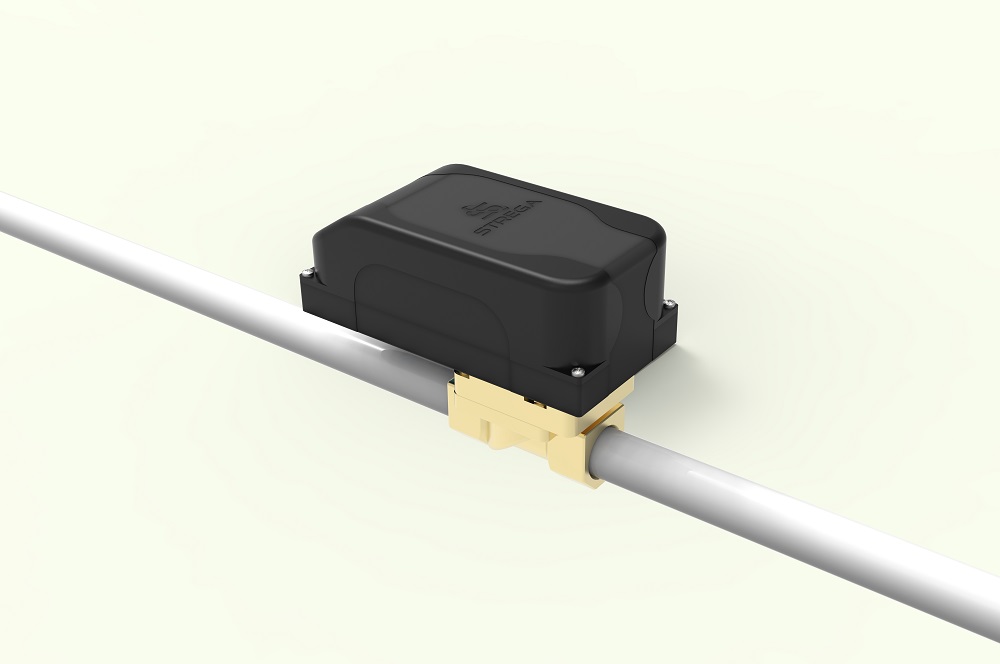

We have hands-on experience in plastic enclosure design of various electronic components. Our plastic enclosure designs are done considering moulding feasibility in the design stage itself, which reduces production time and cost. We use snap fits, interlocking joints, threaded fasteners, glue for connections based on application and customer requirements.

Aesthetic and attractive enclosures are highly preferred by customers and we have a strong foot in such design. We also suggest suitable material and material thickness based on the application and usage of the product. We also give product shape and structure based on the application of the product. We can also modify the existing enclosures as per customer’s specifications. We not only give fit to the product,We give look to your product.

The major type of Plastic casing design we do are for

We offer Customized plastic enclosure design for consumer electronics, telecom & medical products. Adhering to design standards and considering Design for manufacturing (DFM) points is one of the points we stick to, in order to come up with the design which is easy to manufacture and ultimately the tooling cost will also get reduced.

We also consider (Ingress Protection) IP Rating chart as per clients requirement. We also undertake prototyping/low volume batch production services by 3D printing, Vacuum casting.

© 2025 Radiant Design. All Rights Reserved.Developed by Innov Touch Technologies Pvt Ltd